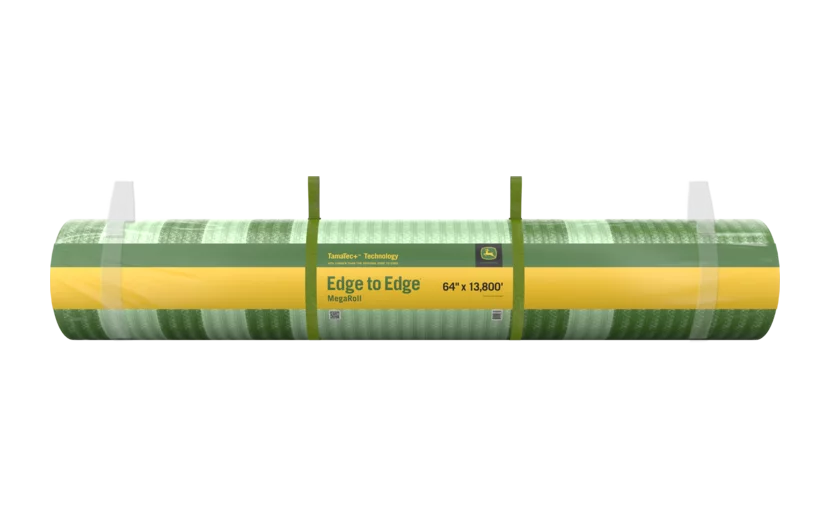

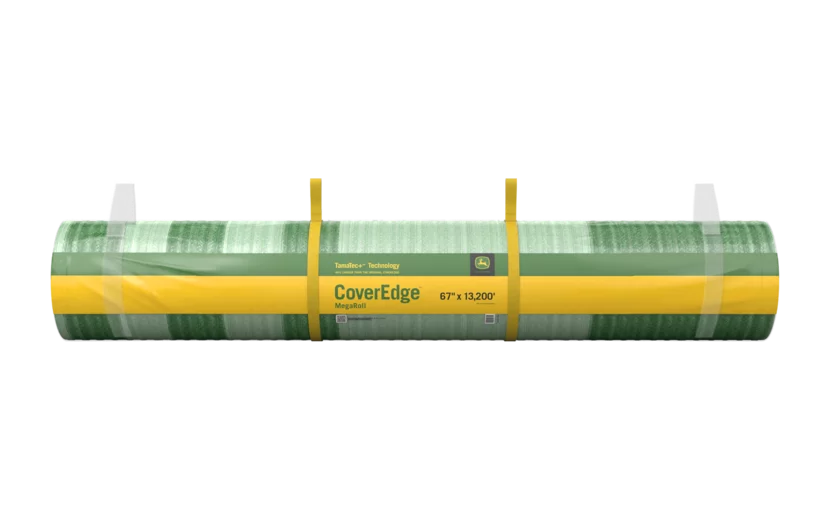

John Deere Edge to Edge TT+

Length:

13,200 FT MINIMUM GUARANTEE

John Deere Edge to Edge® is specifically designed for your John Deere baler, ensures the perfect baling experience. It offers more bales per roll, superior crop protection for longer-lasting bales, and a lower cost per bale. With increased footage per roll, achieving 10-15% more bales per roll, John Deere Edge to Edge® enhances baler productivity and reduces downtime.

Edge to Edge was designed for 5 and 6 Series balers. It can also be run in newer balers as well.

Edge to Edge was designed for 5 and 6 Series balers. It can also be run in newer balers as well.

A unique striping pattern with clear 'left/right' indicator.

Fitted for increased safety and convenience during transport and handling.

Each roll contains AT LEAST the exact stated length.

Every roll contains a visible Roll End warning stripe, which shows the end of the roll is approaching.

We're here to help tackle any problem. Our experts are available to offer technical support whenever you need it.

Each roll includes its own unique "passport", enabling the tracing of complete production details.

Technologies

Specifications

| Product Name | Length | Width | Diameter | Rolls per Pallet |

|---|---|---|---|---|

|

John Deere Edge to Edge TT+

|

13,200 FT MINIMUM GUARANTEE

|

48"

|

11"

|

16

|

Product Name

Length

Width

Diameter

Rolls per Pallet

John Deere Edge to Edge TT+

13,200 FT MINIMUM GUARANTEE

48"

11"

16

1 Products

Locate the nearest professional

Browse your contact man by State

- AL

- AK

- AZ

- AR

- CA

- CO

- CT

- DE

- FL

- GA

- HI

- ID

- IL

- IN

- IA

- KS

- KY

- LA

- ME

- MD

- MA

- MI

- MN

- MS

- MO

- MT

- NE

- NV

- NH

- NJ

- NM

- NY

- NC

- ND

- OH

- OK

- OR

- PA

- RI

- SC

- SD

- TN

- TX

- UT

- VT

- VA

- WA

- WV

- WI

- WY

Results (21)

Results (21)

Tama USA TamaWrap Sales Operations Manager

Mike Dodds

Mike manages TamaWrap sales, supports field representatives and coordinates technical support to customers from our Dubuque IA office.

Read more about

Mike

R&D Management CTO

Reuven Hugi

As a global company that operates worldwide and in different climates, we must bring the best and most innovative products with excellent...

Read more about

Reuven

Tamanet Sales Manager Region

Angel Lopez

AL | AK | AZ | AR | CA | CO | CT | DE | FL | GA | HI | ID | IL | IN | IA | KS | KY | LA | ME | MD | MA | MI | MN | MS | MO | MT | NE | NV | NH | NJ | NM | NY | NC | ND | OH | OK | OR | PA | RI | SC | SD | TN | TX | UT | VT | VA | WA | WV | WI | WY

When it relates to Turf Netting, Angel is the one you need. With over 25 years of experience, he’s likely to have...

Read more about

Angel

Tama Assist Technical Manager

Matt McWilliams

Matt provides unique on-farm experience in the industry, with 25+ years in production ag and nearly 20 years in sales. Your success...

Read more about

Matt

Marketing Development Manager

Ron Amos

Ron has 15+ years with Tama, an additional 50+ years of experience with crop baling products, and a vast amount of in-field...

Read more about

Ron

Tama USA Sales & Marketing Rep.

Annette Bitto

AL | AR | FL | GA | LA | MS | MO | NC | SC | TN | VA

Annette brings a lifetime of cotton experience to Tama, and she understands the importance of being able to get one’s crop harvested.

Read more about

Annette

Tama USA TamaWrap Cotton Support

Norlan Sapp

AZ | CA | NM | TX

Norlan has 15+ years of experience supporting cotton producers and ginners with their TamaWrap needs during harvest. He’s our local go-to expert.

Read more about

Norlan

Sales & Marketing VP

James Cundiff

James leads the TamaWrap team and brings nearly 30 years of experience in the cotton industry, from crop consulting to equipment sales/marketing.

Read more about

James

Tama USA TamaWrap Training & Technical Manager

Joel Basinger

KS | OK | TX

Joel has extensive cotton harvesting support and dealer training experience, and he is also happy to assist ginners in training their employees.

Read more about

Joel

Midwest Territory Manager

Shari Hanson

IA | MN | WI

Shari brings 30+ years of experience in crop baling products, working with valued partners to bring their customers products they depend on.

Read more about

Shari

Product Developent Manager

Doug Stogdill

IA

Doug has been working with Tama since the introduction of John Deere branded twine for Large Square Balers. He’s here to answer...

Read more about

Doug

Northwest Territory Manager

Kyle Madison

CA | ID | OR | WA

Kyle has vast sales experience involving retail agronomy, laboratory services and wholesale fertilizer. Kyle is field ready and able help with all...

Read more about

Kyle

Midwest Territory Manager

Rex Austin

IL | IN | KY | MI | OH

Rex has been helping dealers and farmers find the right baling solutions for 30+ years. If it grows, we can help you...

Read more about

Rex

Southeastern Territory Manager

Joey Peters

AL | FL | GA | LA | MS | SC | TN

Joey has 21+ years with Tama, with an extensive background and experience in the industry that ensures customer confidence when needs arise.

Read more about

Joey

Territory Manager

Joe Pavlovsky

AZ | CO | NV | NM | UT

Joe has worked with Tama for over 6 years. He is happy to explain the value and quality of Tama’s products, so...

Read more about

Joe

Territory Manager

Jim Lee

KS | MO | NE

Jim has worked with Tama dealers and customers for over 10 years. If you need help or advice, he looks forward to...

Read more about

Jim

Territory Manager

Jim Flaska

AR

Jim has 22 years working with Tama crop baling products, selling, servicing, and training, along with 30 years of experience with John...

Read more about

Jim

Territory Manager

Jay Drummond

CT | DE | ME | MD | MA | NH | NJ | NY | NC | PA | RI | VT | VA | WV

Jay has been a territory manager for over 10 years. He understands Best of Class Customer Service and will always respond in...

Read more about

Jay

Territory Manager

Jason Crose

OK | TX

Jason has been a Tama territory manager for over 5 years. As a cattle farmer, he brings his experience to help customers...

Read more about

Jason

Territory Manager

Brad Meckle

MT | ND | SD | WY

Brad has worked with Tama for over 7 years specializing in rounders. He is here to help you with our crop baling...

Read more about

Brad

TamaNet Sales Manager Region

Todd Palmer

AL | AK | AZ | AR | CA | CO | CT | DE | FL | GA | HI | ID | IL | IN | IA | KS | KY | LA | ME | MD | MA | MI | MN | MS | MO | MT | NE | NV | NH | NJ | NM | NY | NC | ND | OH | OK | OR | PA | RI | SC | SD | TN | TX | UT | VT | VA | WA | WV | WI | WY

Are you wondering what’s the best fit for your pallet operations? Start by talking to Todd and the rest will follow.

Read more about

Todd

More ways we can assist

Service request

Knowledge Center

Training

Field experts

Questions about Netwrap?

We’ve got the answers

Questions about

Netwrap Baling Tips

When using Round Bale Netwrap, a few moments must be taken to ensure correct preparation of your machine in order to achieve the best results. The most common problems of net splitting, tearing, or fouling on feed rollers arise from the net ‘laddering’, where threads become broken, leading to a running stitch in the net running opposite to the direction of the net, eventually causing the net to separate where the ‘ladder’ has occurred. This can be caused by many different and varying circumstances but will always have the same ‘ladder’ effect.

Check that the area in which the roll sits is free from dirt and debris. Ensure that all metal surfaces the net comes into contact with are free from rust or sharp edges or weld spots (net box sides, spreader bars and rollers etc.), or dried paint ‘lumps’ on any surfaces which could damage the net. Clean up with emery paper if necessary. Also, check that the path for the net to the bale behind the feed mechanism is not dirty or rusty, which could restrict the net’s passage when feeding – often identified by a ‘lump’ of net at the start of the wrapping cycle. This is especially important when starting baling after winter storage.

Ensure the net is threaded correctly. Incorrect feeding of the net will cause incorrect tension being applied, leading to feeding and cutting difficulties which, in turn, will cause problems on subsequent net feed cycles. Where the net is fed through a series of fixed tension bars, always make sure these are clean and polished to avoid excessive friction. Excessive net friction or an uneven surface will cause the net to tear.

Where two rollers are used to feed the net, it is imperative these are correctly aligned and tensioned against one another, to enable the net to feed in evenly and under the correct tension. Incorrectly aligned rollers will produce a corresponding uneven net feed and subsequent cutting action at the end of the wrapping cycle. This will result in poor bale coverage and possible net fouling on the feed rollers at the start of the next cycle. The rollers’ surface should also be closely inspected for abrasions or damage, which could snag the net when feeding.

Ensure the feed rollers are clean of any moisture or residue. Never use an aggressive cleaning agent such as petrol or turpentine to clean rubber rollers.

Always dust rubber rollers down with French chalk or talc powder when loading a new roll of Netwrap, or use anti-static spray to reduce net static when operating. This avoids the net fouling and wrapping around the rollers when feeding in.

Carefully inspect the condition of the belt joiners on variable chamber balers for damage or worn connections, as this will snag the net and cause a tear, which will split the net on the bale.

Make sure the knife or cutting surface is clean and undamaged. Poor cutting action will result in an uneven ‘tail’ to the net, which can become tangled in the rollers and feed mechanism.

Check that the area in which the roll sits is free from dirt and debris. Ensure that all metal surfaces the net comes into contact with are free from rust or sharp edges or weld spots (net box sides, spreader bars and rollers etc.), or dried paint ‘lumps’ on any surfaces which could damage the net. Clean up with emery paper if necessary. Also, check that the path for the net to the bale behind the feed mechanism is not dirty or rusty, which could restrict the net’s passage when feeding – often identified by a ‘lump’ of net at the start of the wrapping cycle. This is especially important when starting baling after winter storage.

Ensure the net is threaded correctly. Incorrect feeding of the net will cause incorrect tension being applied, leading to feeding and cutting difficulties which, in turn, will cause problems on subsequent net feed cycles. Where the net is fed through a series of fixed tension bars, always make sure these are clean and polished to avoid excessive friction. Excessive net friction or an uneven surface will cause the net to tear.

Where two rollers are used to feed the net, it is imperative these are correctly aligned and tensioned against one another, to enable the net to feed in evenly and under the correct tension. Incorrectly aligned rollers will produce a corresponding uneven net feed and subsequent cutting action at the end of the wrapping cycle. This will result in poor bale coverage and possible net fouling on the feed rollers at the start of the next cycle. The rollers’ surface should also be closely inspected for abrasions or damage, which could snag the net when feeding.

Ensure the feed rollers are clean of any moisture or residue. Never use an aggressive cleaning agent such as petrol or turpentine to clean rubber rollers.

Always dust rubber rollers down with French chalk or talc powder when loading a new roll of Netwrap, or use anti-static spray to reduce net static when operating. This avoids the net fouling and wrapping around the rollers when feeding in.

Carefully inspect the condition of the belt joiners on variable chamber balers for damage or worn connections, as this will snag the net and cause a tear, which will split the net on the bale.

Make sure the knife or cutting surface is clean and undamaged. Poor cutting action will result in an uneven ‘tail’ to the net, which can become tangled in the rollers and feed mechanism.

What is the length of the net?

How many bales can be made from one roll of netwrap?

Is the net strong enough?

Tama Assist

Tama Assist